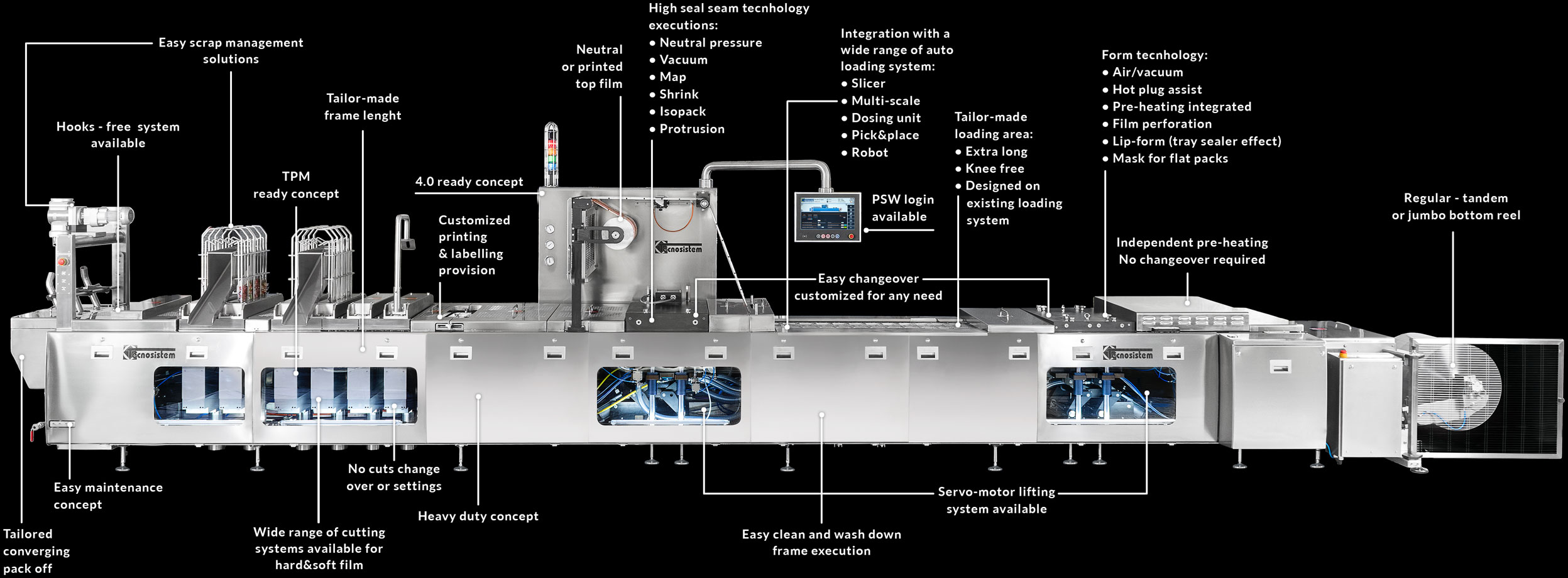

THE MACHINE

Bespoke, noble

materials.

Detailing beyond compare.

Forming station, tray filling, vacuum / MAP, sealing and cutting stations are the rock solid hardware of each thermoforming machine. Entire in-house manufacturing process with premium raw materials through high performance tooling equipment, vanguard electronic software, TPM extra careful hand made, electric assembly and marathon trials gateway: the outcome is a heavy-duty thermoforming machine that withstands the most critical environmental conditions.